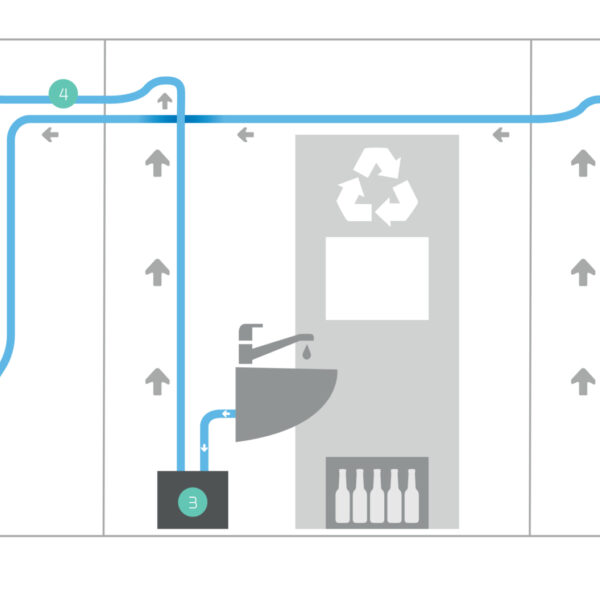

A typical Jets® vacuum system configuration for supermarkets

By using Jets® vacuum technology condensate water is transported vertically to the ceiling, eliminating the need for floor work. When the time comes to remodel there will be no need for covering goods, time consuming concrete work or traditional plumbing. The vacuum system also allows you to continuously monitor its components.

- Unique flexibility

- Easy installation

- A smarter solution

1. Vacuumarator® pump

The Vacuumarator® pump is the heart of our system and supports multiple interceptor tanks. It generates vacuum efficiently while using very little energy. The pump can also handle wash basins, bottle recycling machine drains and toilets.

2. Electronic control unit

Continuous automatic monitoring and control of the pump, valves and interceptor tanks is available.

This keeps the system functioning smoothly, and features alarm signals for easier troubleshooting, service and maintenance.

3. Interceptor tank

Jets® interceptor tanks are installed under freezers and refrigerators to collect condensate water. When the water level reaches a predetermined point, a sensor in the tank triggers the vacuum valve in the ceiling (4) to open. We have interceptor tanks in different sizes to meet your needs.

4. Vacuum valves

Jets® vacuum valves in the ceiling are triggered by sensors in the interceptor tanks. The valves open for a few seconds, enabling the vacuum to lift condensate water vertically up to the ceiling where it enters the main pipe.

5. Vacuum piping

Liquid transport in vacuum pipes is highly efficient and completely independent of gravity. Small-diameter pipes are used, with 32 mm and 50 mm being the most common.

6. Transport pockets

Transport pockets are installed to ensure safe and smooth transport of the condensate water.

7. INT Controller Master

The Controller Masters are used to control INT Interceptor tank and the Vacuum Valve.

Peace of mind with Jets®

An electronic control unit continuously monitors the system.

When water in an interceptor tank reaches a predetermined level, a level switch triggers the valve to open. In a matter of seconds, the water is lifted to the ceiling and transported away.

The control unit also allows you to continuously monitor the system's components with alarm signals for easier troubleshooting, service and maintenance.

A total drainage solution

The Jets® system does not end here

We offer vacuum solutions for wash basins, bottle recycling machine drains and vacuum toilets. Our water saving toilets for wall or floor installation can be placed in locations where traditional toilets are difficult to install.

We have extensive experience with all the above and can provide system design assistance.

If you have any queries regarding your project, please contact us for more information.

Store planning made easy

Free yourself from the constrictions of existing drains and achieve your design vision.

Eliminate the need for costly and time-consuming construction work. When the time comes to remodel there will be no need for disruptive concrete cutting or traditional plumbing.

With Jets® Vacuum technology, planning the layout of a store is not limited by the location of drains. Even last minute changes are not only possible, but easy!

FAQ

Here, you will find answers to questions about Jets® solutions for draining condensation water in shopping centers and stores. If you have a question that you cannot find an answer to, please do not hesitate to contact one of our representatives.

What is vacuum technology for condensate water removal?

Vacuum technology for condensate water removal uses a vacuum system to lift and transport condensate water away from refrigeration and freezer units. It eliminates the need for floor drains and offers a more efficient solution.

How does vacuum condensate water removal work?

Jets® vacuum technology creates a low-pressure area, allowing condensate water to be lifted and transported through vacuum push-fit pipes to a centralized drain in the ceiling, independent of floor drain location.

What are the advantages of using vacuum condensate water removal?

Key benefits include flexibility in unit placement, quick installation, minimal downtime, easy layout changes, user-friendly operation, and low life-cycle costs due to minimal maintenance.

Is vacuum condensate water removal suitable for all types of retail stores?

Yes, Jets® vacuum technology is versatile and suitable for various retail environments, including supermarkets, convenience stores, and foodservice outlets.

What maintenance is required for a vacuum condensate water removal system?

Vacuum systems have few components and require minimal maintenance. Routine checks and occasional cleaning are typically all that’s needed to ensure efficient operation.

Can I retrofit an existing store with a vacuum condensate water removal system?

Yes, Jets® vacuum systems are designed to be retrofitted into existing stores, offering a cost-effective solution for upgrading condensate water management.

What diameter sizes are commonly used in vacuum piping?

Liquid transport in vacuum pipes is highly efficient and completely independent of gravity. Therefore small-diameter pipes are used, with 32 mm and 50 mm being the most common.

How does the Vacuumarator® pump function in the system?

The Vacuumarator® pump is the core of the Jets® system. It effectively generates vacuum while consuming minimal energy and supports multiple interceptor tanks.

How is condensate water collected using vacuum drainage?

The condensate water is gathered in an interceptor tank. Jets® interceptor tanks are installed underneath freezers and refrigerators to collect condensate water. When the water level reaches a predetermined point, a level sensor in the tank triggers the vacuum valve in the ceiling to open.

How many interceptor tanks can be operated by a Vacuumarator® pump from Jets®?

A Vacuumarator® pump from Jets® can handle up to 15 interceptor tanks with a lifting height of up to 5 meters. Each interceptor tanks can handle up to 10 meters of cooling furniture. One Vacuumarator® pump can therefore handle up to a maximum of 150 meters of cooling furniture if the lifting height is less than 5 meters. For higher lifting heights number of interceptor tanks per pump is reduced. But when needed we just add one or two extra Vacuumarator® pumps to the installation.

Are vacuum drainage system more cost-effective than traditional drainage?

Vacuum drainage systems are cost-effective for stores because they offer reduced start-up costs, thanks to easy installation which ensures minimal shop downtime. Their design allows store layouts to be altered swiftly with little disruption, and they're tailored for effortless daily operation by store staff. Additionally, with fewer components, they present low life-cycle expenses owing to minimal maintenance and a prolonged lifespan.